When laying or gluing a Parquet, Laminate, or Vinyl floor, many factors come into play. Moreover, there are different products, such as Vinyl or Herringbone Laminate, which have completely different working methods. This is sometimes greatly underestimated. But can any handyman lay any floor? If you are not careful, you may quickly risk damaging your floor. Below we have listed the five most common mistakes made when laying a floor.

The 5 most common mistakes when laying a floor

1. Laying too fast

An Oak Parquet floor is susceptible to expanding or shrinking considerably with changes in temperature or humidity. This can result in cracking, bulging, rising corners (for floating installations), or cracks in the planks (for glued installations). To minimize this effect, allow the floor to acclimate for at least 48 hours, but preferably several weeks, before installation. Lay the floor in the room where it will be installed to give the floorboards time to acclimate properly. This will help prevent extreme effects on the floor later on.

While this phenomenon is well-known with wooden floors, it is also important to consider normal to wide Laminate and Herringbone Rigid Click Vinyl floors. These floors can sometimes show even more dramatic effects under different conditions. For further information on this topic, read about why a floor needs to acclimate.

2. Calculating sawing loss

When installing a floor, it’s impossible to calculate the exact number of planks or square meters needed. Typically, at the end of each job, there will be a leftover piece of the floorboard. If this piece is still a reasonable length, it can be used for the next job. However, pieces less than 40 cm cannot be used and are considered a sawing loss.

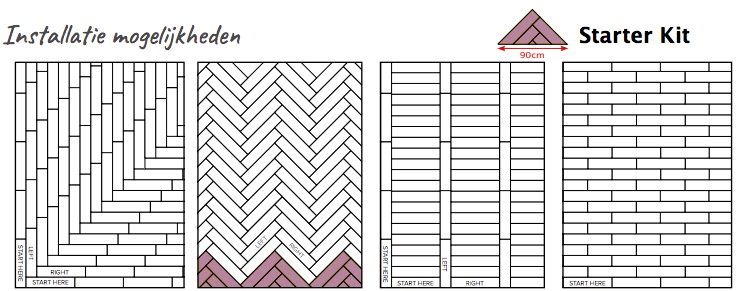

When using a standard laying pattern, it’s important to account for a 7% cutting loss. This loss should be factored in when ordering the number of square meters. Failure to do so may result in not having enough boards to finish the floor, which can be especially frustrating with custom-made wooden products. For other laying patterns, such as herringbone or a ladder, we assume a higher cutting loss of at least 12% for herringbone!

3. Rough surface

Levelling the ground is a requirement when installing Vinyl flooring. This is because the substrate needs to be completely smoothed out and levelled with levelling compound to prevent any unevenness from showing through the flexible material. As for laminate and parquet flooring, there is no standard answer. If you plan to glue down a parquet floor, a level substrate is certainly important. However, if you opt for a floating installation of laminate or parquet with the right underlay, it can compensate for some difference in the subfloor.

Underlay boards are a good option for rough subsurfaces. However, it’s important to note that the underlay is not a levelling agent. Its primary purpose is to support and protect the floor against issues such as rising dampness from the substrate. While a flat and level surface is important for laminate and parquet, it is required for dryback vinyl, such as Floer Country House Vinyl.

4. Tight against the wall

This is a well-known recommendation often found on the packaging of parquet, laminate, rigid click vinyl, and dryback vinyl floors. However, it is still sometimes overlooked despite the importance of allowing the floor to lie freely. By doing so, the floor has room to expand when in use.

Sometimes, people also overlook the 1 cm clearance between the wall and the floor. In places where a high skirting board cannot be placed, such as near the door frame, the floor is sometimes laid tight to the wall. While it may not seem like a big issue in a few places, it is still important to leave enough clearance as the floor surface can lose its effect if it cannot expand and contract properly. This can become evident later on.

The results of not leaving enough clearance when installing flooring can include bulges in the floor, cracked floors, broken joints, or even damaged boards. Therefore, it’s important to maintain a 1 cm clearance everywhere, even in places where it may be inconvenient. There are various alternative solutions for door frames and thresholds, such as cover strips, skirting boards, and strips. For dryback vinyl, like the Floer Tile Vinyl, the clearance can be a bit smaller and possibly finished off with a sealant edge. However, even in this case, a few millimeters of clearance are still necessary for proper operation.

5. Skipping the instructions

This may sound trivial, but it is one of the most common mistakes made when laying Laminate flooring. Often, a family member or friend who has laid laminate before will jump into the project without reading the installation instructions, relying on their previous experience. However, not all laminates are created equal – there are many different click connections that require different installation methods. For instance, a floor with Variclick cannot be laid in the same way as one with a Fastclick connection. If you attempt this, there is a high chance that the boards will not connect properly. This often leads to people applying more force to make the connections fit, which can result in joints breaking off. It is crucial to read and follow the installation instructions carefully to avoid such problems.

Each joint has its own method. Consider important points such as: which side to start with, whether to slide the planks together while lying down or push them down to join them, and whether to lay the floor plank by plank or in full courses. Therefore, it is highly recommended to read the installation instructions carefully. Taking a few extra minutes to do so can actually save you a lot of time during installation!

Tip: when tapping planks directly onto the floor, avoid using a hammer. Various tapping blocks are available to protect the joint of the plank. It is often a good idea to order the corresponding installation set, which includes a stop block as well as spacers and other necessary accessories.

Are you feeling unsure? Choose a specialist!

Not sure about laying your own floor? We recommend using a specialist for flooring, especially for herringbone bonding (except for simple herringbone laminate with click connections and starter kits). Installing an oak wood herringbone floor, wide vinyl, whalebone vinyl, or herringbone vinyl floor requires a professional with the right training and education, as these floors are glued to the substrate. As a handy DIY-er, you are free to tackle these more complex floors but be prepared for a less-than-perfect result.

Questions about installation?

Learn how to lay a Herringbone Click vinyl floor yourself with our helpful floor-laying videos. No need for a parquet installer or installation service! If you’re interested in laying wide laminate, read our guide on how to do it. If you have any questions, feel free to contact Team Floer or your nearest dealer. We’re always happy to help. Already chosen a Floer? Order a sample to see if it suits your home!